420,000 people die from food-borne illness annually, and around 600 million people, almost 1 in 13 people worldwide, fall ill after consuming contaminated food each year. This results in a staggering loss of 33 million healthy life years.

As a canteen or catering manager, food safety compliance is something you cannot afford to ignore.

Foodborne illnesses can have detrimental effects on your bottom line, including reputational damage, financial losses, and potential legal consequences.

Prioritizing food safety, compliance with regulations, and proper hygiene practices can safeguard your customers and protect your business.

This includes rigorous standards for food handling, storage, and preparation, as well as regular monitoring of temperature control, sanitation, and hygiene practices.

Let’s walk through the causes of poor food safety and how to address them.

5 causes of poor food safety in canteens and catering operations

Think of food safety in your establishment like a building’s foundation.

Just as a strong foundation is crucial for stability, proper food safety practices are the foundation of a successful food service operation. Without it, the operation risks collapse.

I’ves worked in several restaurants and catering operations and have identified 5 common areas where food safety gets compromised:

- Inadequate training and supervision

- Poor communication and coordination

- Inefficient processes and workflow

- Lack of proper monitoring and documentation

- High food volume and turnover

#1 Inadequate training and supervision

It can be difficult ensuring consistent training and supervision with a high number of staff members handling food.

Staff may not be properly trained in food handling practices, leading to mistakes, cross-contamination, and other food safety breaches.

For example, improperly mixing raw and cooked foods may result in cross-contamination, leading to foodborne illnesses.

#2 Poor communication and coordination

In large operations, communication breakdowns can occur, leading to misinterpretation or misinformation about food safety protocols.

For instance, miscommunication about storage temperatures or food handling procedures among different sections of a large catering operation can result in unsafe food practices and potential foodborne illness outbreaks.

#3 Inefficient processes and workflow

Large operations may have complex processes for food procurement, storage, preparation, and serving.

If these processes are not streamlined and efficient, it can lead to delays, mistakes, and increased risk of food contamination.

For example, the process of getting food for a big restaurant or hospital café chain involves a number of steps, such as finding suppliers, negotiating contracts, placing orders, and arranging deliveries.

If these steps are not well-coordinated or automated, it can cause delays in getting ingredients, inventory shortages, or even getting low-quality goods.

#4 Lack of proper monitoring and documentation

Monitoring food safety practices and keeping accurate records can be challenging in large operations.

Without proper monitoring and documentation, it becomes difficult to identify and address potential issues, leaving the operation vulnerable to food safety risks.

For example, in a hotel, the kitchen staff must check and keep the right temperature controls for storing and preparing food on a regular basis.

By keeping careful records of temperatures and doing regular checks, the hotel can find any problems or possible dangers, like improper storage or cross-contamination.

Then, quick action can be taken to fix the problem and prevent food-borne illnesses, which will eventually protect the guests’ health.

#5 High food volume and turnover

Large canteens and catering operations often handle a high volume of food, within a short period.

This can increase the risk of cross-contamination, improper storage, and inadequate temperature control, leading to foodborne illnesses.

For example, in a large canteen or catering operation, quick turnover of food items may result in inadequate time for proper cleaning and sanitizing of utensils, surfaces, and equipment, increasing the risk of food contamination.

The 4 Cs of food safety, handling, storage, and preparation

Direct cross-contamination occurs when contaminated food comes into contact with other food, spreading the contamination.

This can happen through poor storage arrangements or improper handling of raw meat and unwashed fruits and vegetables.

Indirect cross-contamination occurs through contaminated kitchen surfaces, hands, equipment, or other objects.

To prevent cross-contamination, maintain strict separation between raw and ready-to-eat food, practice effective cleaning and disinfection procedures, and ensure high personal hygiene standards, including thorough hand washing.

The 4 Cs of food safety can help prevent food contamination and protect the health of your consumers:

- Cleanliness: Ensure that food handling areas, utensils, and equipment are kept clean and sanitized to prevent the spread of harmful microorganisms. Use a high-quality sanitizer solution (at least 70% alcohol) to achieve this and aim for a regular cleaning schedule clearly communicated to all your staff.

- Cross-contamination: Avoid cross-contamination by keeping raw and ready-to-eat foods separate, using separate cutting boards and utensils, and practicing proper hygiene when preparing and storing food.

- Cooking: Ensure food is cooked to the appropriate temperature to kill harmful microorganisms and prevent foodborne illnesses.

- Chilling: Properly store perishable foods in refrigeration to slow down the growth of harmful microorganisms and prevent spoilage.

Food handling and cleaning

Hand hygiene is crucial in food preparation to prevent the spread of harmful microorganisms.

Food handlers should always wash their hands carefully with soap and water before touching food, after touching raw food, after using the bathroom, and after touching surfaces that could be contaminated.

They should wash their hands for at least 20 seconds and use a clean towel or air fan to dry them.

To avoid cross-contamination, regularly clean and scrub surfaces, tools, cutting boards, and equipment.

Cleaning means getting rid of dirt and debris that you can see, while sanitizing means getting rid of invisible dangerous microorganisms to a safe level.

Temperature control

Keeping food from getting people sick is mostly about keeping the temperature right. Keep perishable foods, such as meats, poultry, fish, dairy products, and ready-to-eat foods, at safe temperatures to stop dangerous microorganisms from growing.

Refrigerator temperatures should be at or below 40°F (4°C), while freezers should be at or below 0°F (-18°C).

Chill food as soon as it is done cooking so it doesn’t spend too much time in the temperature danger zone, which is between 40°F and 140°F (4°C and 60°C).

Thermometers and weather logs can help you monitor temperature. Use calibrated thermometers to check the internal temperature of foods, especially meats, poultry, and fish, to make sure they are cooked to safe temperatures. You can grab one online at Amazon or Takealot.

Use temperature logs to record and monitor temperatures at crucial control points including refrigerators, freezers, and food holding units.

A temperature log allows you to quickly discover temperature concerns and take corrective action.

Canteen temperature log sheet template

Download the following free temperature log sheet to monitor temperature levels in your canteen or catering operation:

Compliance with food safety regulations in South Africa

The following departments are responsible for food legislation in South Africa:

- The Department of Agriculture, Forestry and Fisheries (DAFF)

- The National Department of Health

- The Department of Trade and Industry

The Department of Health in South Africa has established regulations that must be adhered to by all food businesses to prevent foodborne illnesses.

To make sure food safety laws are being followed, they conduct checks and audits on a regular basis.

The local health department may send inspectors to your kitchen or catering business to make sure food is stored, handled, and cooked correctly.

5 types of food safety and hygiene training in South Africa

Your staff should be well equipped to handle food safely. This includes obtaining certifications, such as a Food Handler Certificate, and ongoing professional development.

Proper training can help prevent food contamination, cross-contamination, and foodborne illnesses. Let’s explore a few of them:

Basic food handling and hygiene training

A type of training that teaches people who work with food the basic rules of food safety and health.

This training covers a wide range of topics, such as the right way to handle food, personal hygiene, cleaning and sanitizing surfaces and tools, safe food storage, and how to avoid cross-contamination.

Such training is important for chefs, cooks, waiters, and anyone else who works with food professionally. It helps to make sure that food is prepared and given in a safe way, which lowers the risk of foodborne illness outbreaks.

Allergen training

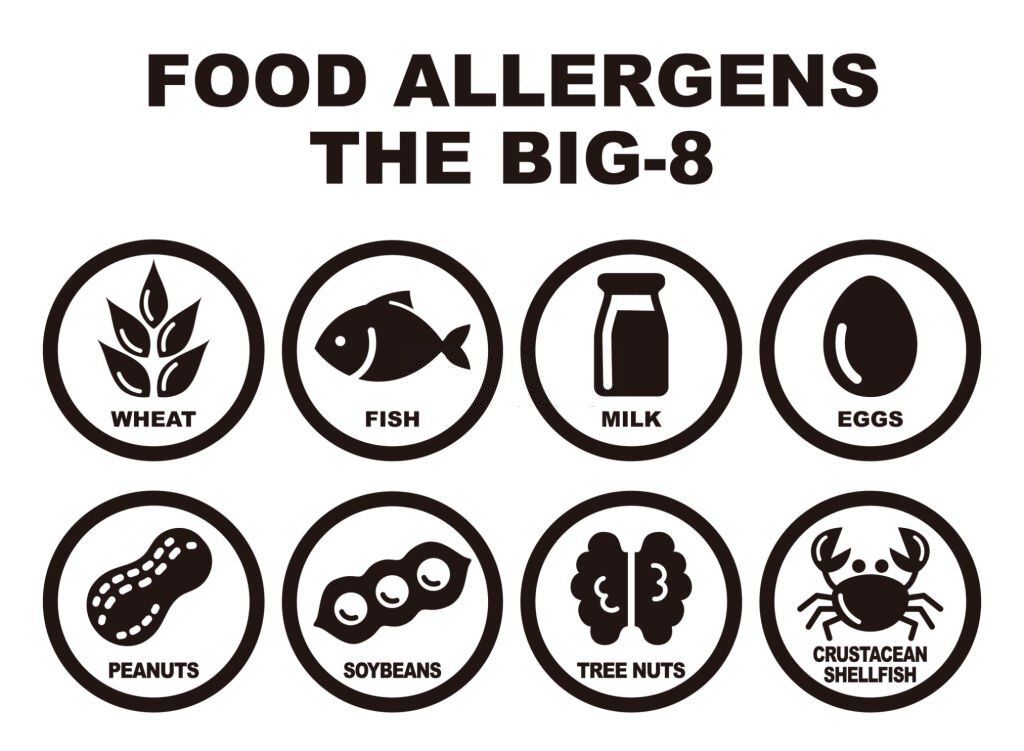

This training focuses on how to find food allergens and deal with them, as well as how to handle allergic responses.

Food workers should know about the most common allergens, like peanuts, tree nuts, shellfish, eggs, and dairy, and how to avoid cross-contamination when preparing and serving food.

Allergen training also includes how to deal with people who have food allergies and how to give first aid in case of an allergic reaction.

Hazard Analysis and Critical Control Points (HACCP) training

This helps your staff understand the basic ideas behind HACCP, which is a method for finding and reducing possible risks in the food production process.

The training shows employees how to find potential dangers and key control points in the production process, as well as how to use control measures to stop or get rid of those dangers.

It also covers how to keep track of and write down the control measures, as well as what to do if there is a problem with food safety.

Food safety management training

This training looks at the ideas and requirements of food safety management systems like ISO 22000 and the Food Safety Modernization Act (FSMA).

The training is meant to teach people how to set up and keep up a food safety management system, which is a way to find and control possible hazards in the food production process in a systematic way.

Most of the time, the training includes things like hazard analysis, risk assessment, control measures, and procedures for monitoring and verifying.

It also talks about documentation and record-keeping needs, as well as how important it is for everyone in the company to talk to each other and get training.

Regulatory compliance training

Food labeling, adequate temperature control, and cleanliness standards may be covered in regulatory compliance training.

The purpose of regulatory compliance training is to guarantee that the operation meets all the necessary criteria to maintain food safety while avoiding penalties or legal difficulties associated with noncompliance.

Food safety and hygiene training providers in South Africa

Here’s where you can get each of the above types of training in South Africa:

- Basic food handling and hygiene training

- Entecom: Provides entry-level courses on food safety and hygiene practices, offering skills certificates.

- Udemy: Offers online training platforms with a variety of food handling courses.

- Allergen training

- Allergy Foundation of South Africa (AFSA): Provides online training with CPD accreditation, focusing on allergies and food safety.

- Hazard Analysis and Critical Control Points (HACCP) training

- MiChem Dynamics (Pty) Ltd: Offers comprehensive food safety consulting, auditing, and training services, ensuring compliance with various standards.

- Nelson Mandela University: Provides short courses on HACCP.

- Food safety management training

- Aspirata Auditing Testing and Certification: Assesses food-related industries for certification according to ISO/IEC 17021:1-2015.

- BSI: Produces technical standards and offers a variety of courses on food safety management systems.

- Regulatory compliance training

- Safetycloud: Delivers industry-leading training in food safety, offering courses online, at training venues, or on-site. Covers topics such as basic food safety, hygiene, and more.

Managing food allergies and special dietary requirements in catering

I recently visited Food Lover’s Market Eatery to buy a lactose-free smoothie.

When I asked the staff member behind the smoothie desk some questions, it became clear they didn’t know or understand what dairy-free or lactose intolerance meant.

This lack of knowledge and understanding from staff can be a major turnoff for customers, leading them to leave your shop and seek alternatives elsewhere.

This is because failure to identify and manage food allergies or dietary restrictions can result in cross-contamination and serious health consequences for individuals with food allergies or intolerances.

Educate your staff on different types of food allergens, intolerances, and special dietary requirements, such as vegan, vegetarian, lactose intolerant, and gluten-free diets.

Label all food products accurately with their allergen information and be clear when discussing special dietary requests with customers. This builds consumer trust.

Also, having an emergency plan for dealing with allergic responses and training staff on how to give first aid and use an EpiPen can help keep customers safe.

Frequently reviewing and altering your menu to accommodate customers with special dietary requirements can keep them satisfied and devoted.

Final words on food safety, hygiene, and compliance

You can keep an eye on your food hygiene habits by asking yourself the following questions:

- Do my employees have the necessary training for safe food handling?

- Are they sanitizing and cleaning tools and surfaces according to the right procedures?

- Do I frequently check the equipment used to cook and store food for temperature?

- Do I regularly conduct audits and keep track of my food safety procedures?

Proactively take the following steps to ensure the sanitation and safety of food operations:

- Educate employees properly about safe food handling procedures

- Clean and sanitize equipment and surfaces regularly

- Monitor and maintain appropriate food storage and cooking temperatures

- Keep records of food safety practices and conduct regular audits

Glossary: Food safety terms to know

Here are some important terms to familiarize yourself with:

- Foodborne illness, also known as food poisoning or foodborne disease, results from consuming contaminated food or beverages and may cause symptoms like nausea, vomiting, diarrhea, abdominal pain, and fever.

- Pathogens are microorganisms, including bacteria, viruses, parasites, and fungi, that can cause foodborne illnesses. Examples include Salmonella, E. coli, Norovirus, and Listeria.

- Contamination refers to the presence of harmful substances or microorganisms in food, which can cause foodborne illnesses. It can occur during production, processing, handling, storage, and preparation of food.

- Cross-contamination happens when harmful microorganisms are transferred from one food or surface to another, leading to contamination. For instance, using the same cutting board or knife for different foods without proper cleaning and sanitizing can result in cross-contamination.

- Food safety hazards are factors that can make food unsafe for consumption, such as poor hygiene practices, improper storage temperatures, presence of allergens, and foreign objects in food.

- Hazard Analysis Critical Control Points (HACCP) is a systematic approach for identifying, evaluating, and controlling food safety hazards throughout the food production process. It involves identifying critical control points, implementing controls, and monitoring and verifying their effectiveness.

- Food recall is the process of removing and/or correcting food products from the market due to actual or potential food safety hazards. Food recalls can have serious consequences for businesses, including financial losses and reputational damage.

- Foodborne outbreak refers to a cluster of foodborne illnesses that are linked to a specific food or food establishment. Outbreaks can occur due to various factors, such as contamination during production, improper storage, or inadequate food handling practices.

By ensuring food safety and hygiene, you can protect your customers’ health and maintain a positive reputation.